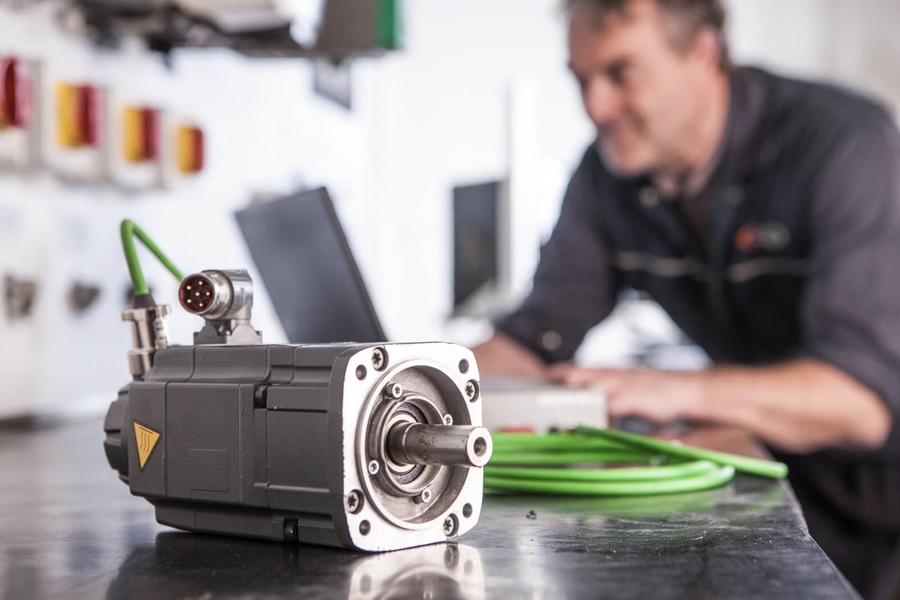

Servo motors are integral components in various industries, powering machinery with precision and efficiency. However, like all mechanical devices, they are subject to wear and tear, leading to potential failures. When faced with a malfunctioning servo motor, the choice between repair and replacement becomes critical. This article explores the factors to consider when making this decision, providing insights tailored to the Dubai and UAE region.

Understanding Servo Motor Failures

Servo motor failures can occur due to various reasons, including electrical faults, overheating, mechanical wear, and environmental factors like dust or moisture. Identifying the exact cause of failure is essential before deciding on repair or replacement. In Dubai’s industrial environment, where extreme temperatures and dust are common, motors are particularly susceptible to these issues. Regular maintenance and timely interventions can mitigate the risk of failure, but when breakdowns do occur, a thorough assessment is necessary to guide the next steps.

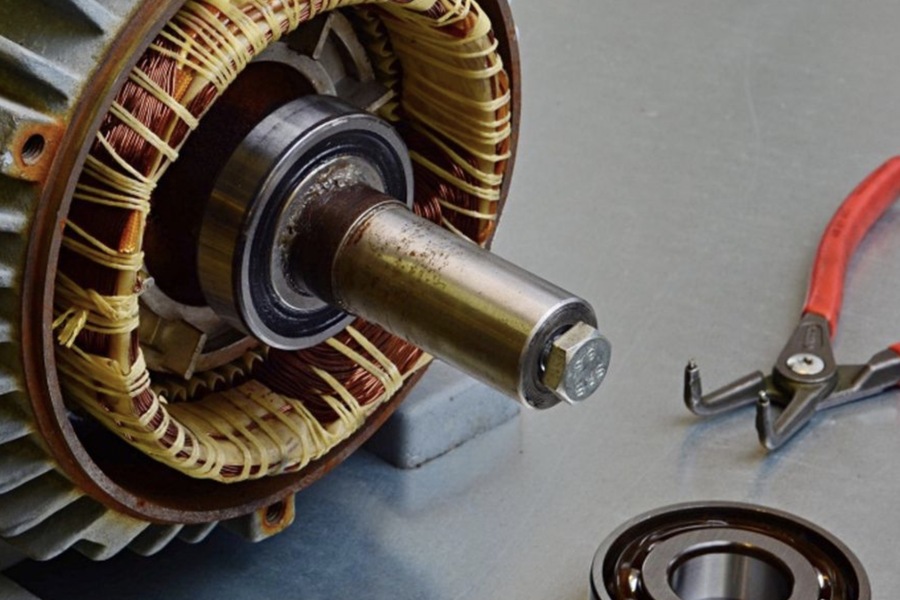

Factors to Consider: Cost Analysis

One of the primary considerations when choosing between repair and replacement is cost. Repairing a servo motor can often be more economical, especially if the damage is minor or isolated to a specific component, such as bearings or encoders. However, repeated repairs can add up over time, potentially exceeding the cost of a new unit. Replacement might be more cost-effective if the motor is old, has suffered extensive damage, or the repair costs approach 50-60% of the new motor’s price. For businesses in Dubai, where operational costs are high, a detailed cost analysis is crucial to avoid unnecessary expenses.

Downtime and Operational Impact

In industries where continuous operation is vital, such as manufacturing, any downtime can lead to significant losses. Repairing a servo motor might take less time if parts are readily available and the issue is straightforward. On the other hand, sourcing a new motor can sometimes be quicker, especially if repair services are delayed or spare parts are scarce. Companies in the UAE need to evaluate their operational priorities, considering the potential impact on production schedules and revenue when deciding between repair and replacement.

Technological Advancements and Compatibility

Servo motor technology evolves rapidly, with newer models offering improved efficiency, precision, and features that older units may lack. When a motor fails, it is an opportunity to consider upgrading to a more advanced model. This is particularly relevant in Dubai, where industries are pushing towards automation and digital transformation. Replacing an old motor with a newer, more efficient model can enhance overall performance and align with long-term business goals. However, compatibility with existing systems must be assessed to ensure that integration of a new motor does not lead to further complications or additional costs.

Environmental Considerations

Sustainability is becoming a significant factor in industrial decision-making, and the choice between repairing or replacing a servo motor can impact a company’s environmental footprint. Repairing extends the life of existing equipment, reducing waste and the demand for new resources. In contrast, replacement contributes to the growing problem of electronic waste. In the UAE, where environmental regulations are increasingly stringent, companies might opt for repair to align with sustainability goals, provided that the repair is viable and does not compromise performance.

Availability of Expertise and Services

The availability of skilled technicians and reliable repair services is another critical factor. In the UAE, companies like Ghaima Group offer specialized servo motor repair services, providing a cost-effective and reliable alternative to replacement. Their expertise can significantly influence the decision, especially when repairs can restore the motor to near-new condition. On the other hand, if local expertise is lacking or the repair facility is not equipped to handle specific types of failures, replacement might be the better option.

Warranty and Future Reliability

Considering the future reliability of the servo motor post-repair is essential. Repaired motors might not always perform at the same level as new ones, particularly if the repair involves temporary fixes or suboptimal parts. Warranty coverage can also differ significantly between repaired and new motors. New motors typically come with a comprehensive warranty that provides peace of mind regarding future performance. For businesses in Dubai, where operational reliability is paramount, opting for replacement may offer better long-term assurance.

Industry Standards and Compliance

Adherence to industry standards and compliance requirements can influence the decision-making process. In sectors such as aerospace, automotive, and medical devices, stringent standards govern equipment performance and safety. A repaired servo motor must meet these standards, which might not always be possible depending on the extent of the damage and the quality of the repair. In the UAE, where industries are increasingly focused on compliance and certification, replacement might be preferred to ensure adherence to regulatory requirements.

Evaluating Long-Term Value

When deciding between repair and replacement, considering the long-term value is crucial. While repair may offer a short-term solution, it might not always provide the best return on investment if the motor continues to have issues. Replacement, although potentially more expensive upfront, can offer a more reliable and efficient solution, reducing future maintenance costs and enhancing overall productivity. In Dubai’s competitive industrial landscape, investing in reliable and efficient equipment can provide a significant advantage.

Conclusion

The decision to repair or replace a servo motor depends on a comprehensive evaluation of various factors, including cost, downtime, technological advancements, environmental impact, availability of expertise, warranty, compliance, and long-term value. In Dubai and the broader UAE region, where industries are rapidly evolving and operational efficiency is critical, this decision must be made with careful consideration of all these aspects. By partnering with experienced service providers like Ghaima Group, businesses can ensure that they make the most informed and beneficial choice, balancing immediate needs with future goals. For more guidance on industrial equipment maintenance and repair, you can explore Dubai Municipality’s official guidelines on industrial safety and compliance.

Biker, traveler, drummer, Bauhaus fan and RGD member. Performing at the fulcrum of beauty and mathematics to craft meaningful ideas that endure. Concept is the foundation of everything else.